Product

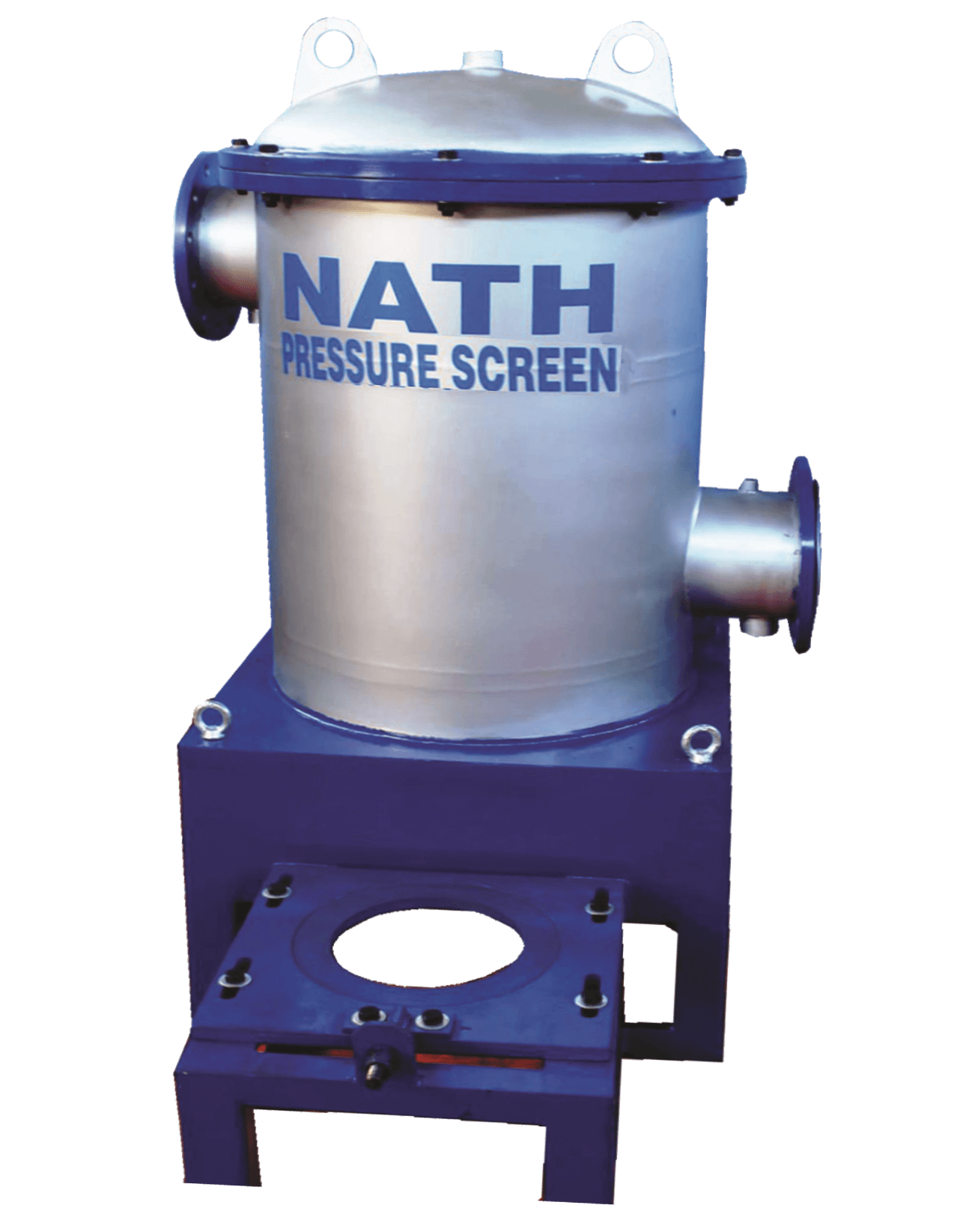

Nath Screen

LOW CONSISTENCY PRESSURE SCREEN

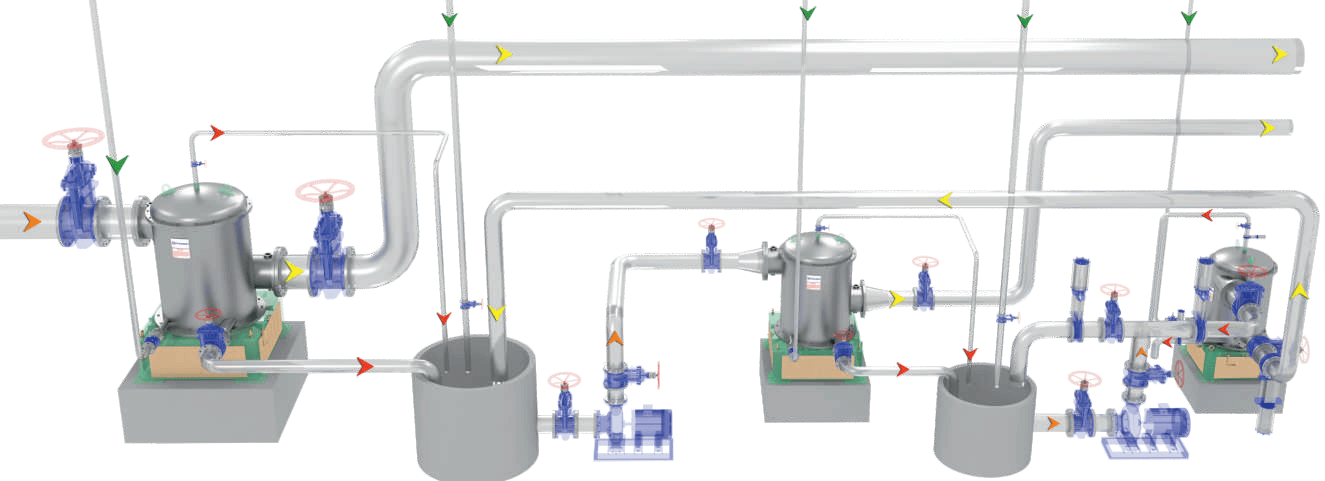

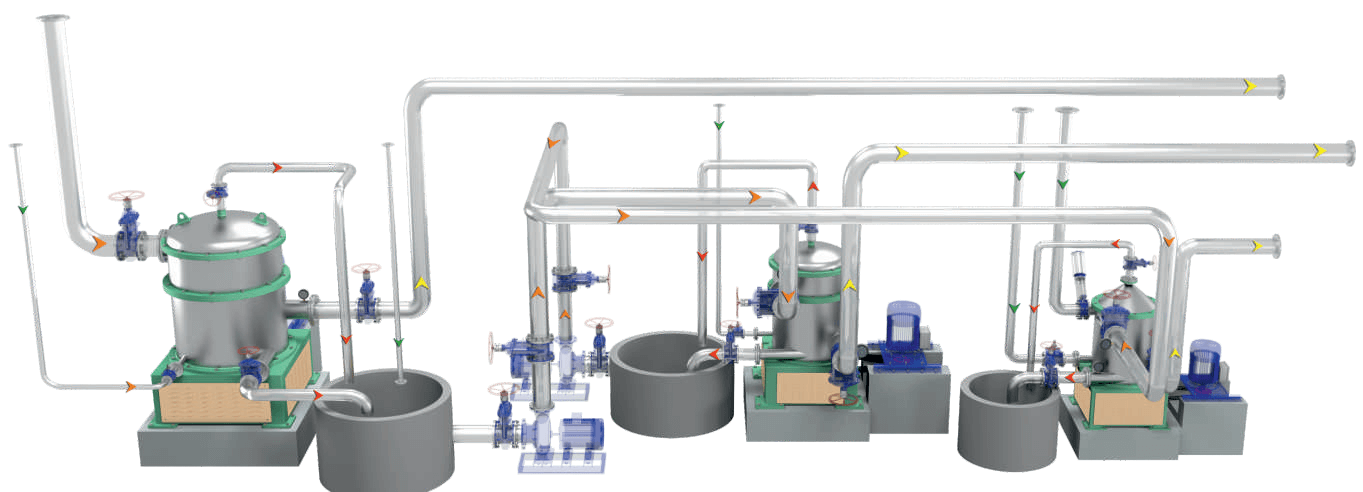

Nath Screen offering extensive range of LC Pressure Screen which finds usage as screening equipment. These LC Pressure Screen is highly power efficient and helps in generation of superior quality paper. LC Pressure Screen is used at Paper Machine Section or will be used for making high quality Fine papers. Vertical Screen is designed for fine screening of all kind of stock suspensions.

Technical Specifications:

- Vertical screen is especially designed to carry out screening of various type of stock present at usually low consistent range of 0.4 – 1.1%.

- The screens are ideally suited for approach flow system and stock manufacturing system besides paper machine

- The multivane aerofoil rotor design ensure free operation of screen from pulsation.

- Improves screening efficiency

- Low energy consumption

- Excellent quality paper

| MODEL NVSL | 4 | 5 | 6 | 8 | 9 | 10 |

| Basket Area (sq.m) | 0.4 | 0.8 | 1.4 | 2.0 | 2.5 | 3.1 |

| Capacity (TPD) | 10-20 | 20-30 | 40-80 | 80-120 | 100-160 | 150-250 |

| Power Kw | 20* | 30* | 45* | 45* | 55* | 90* |

Nath Screen

MEDIUM CONSISTENCY PRESSURE SCREEN

We are involved in manufacturing and supplying an extensive range of MC Pressure Screen which is highly energy efficient. Our range is perfect for preparation of waste paper stock. These have special rotor design which allows the screen to operate with consistency of 3 to 4.5 %. Our stock suspension is screened using screen drum having slots as well as perforation. It is used in Pulp Mill for medium consistency.

Technical specifications:

- Reliable operation and long lifespan

- Exceptional growth in screening competency

- Low-pulsation rotor.

- Better quality

- Competent contaminant segregation

- Less consumption of power

- outstanding manufacturing strength

- Heavy & Sturdy Construction

- All parts coming to contact with the stock are made of stainless steel

| MODEL NVSL | 4 | 5 | 6 | 8 | 9 | 10 |

| Capacity (TPD) | 10-25 | 30-50 | 50-100 | 80-150 | 150-200 | 150-250 |

| Power (Kw) | 22* | 37* | 45* | 55* | 90* | 110* |

| Motor (RPM) | 1470 | 1470 | 1470 | 1470 | 980 | 980 |

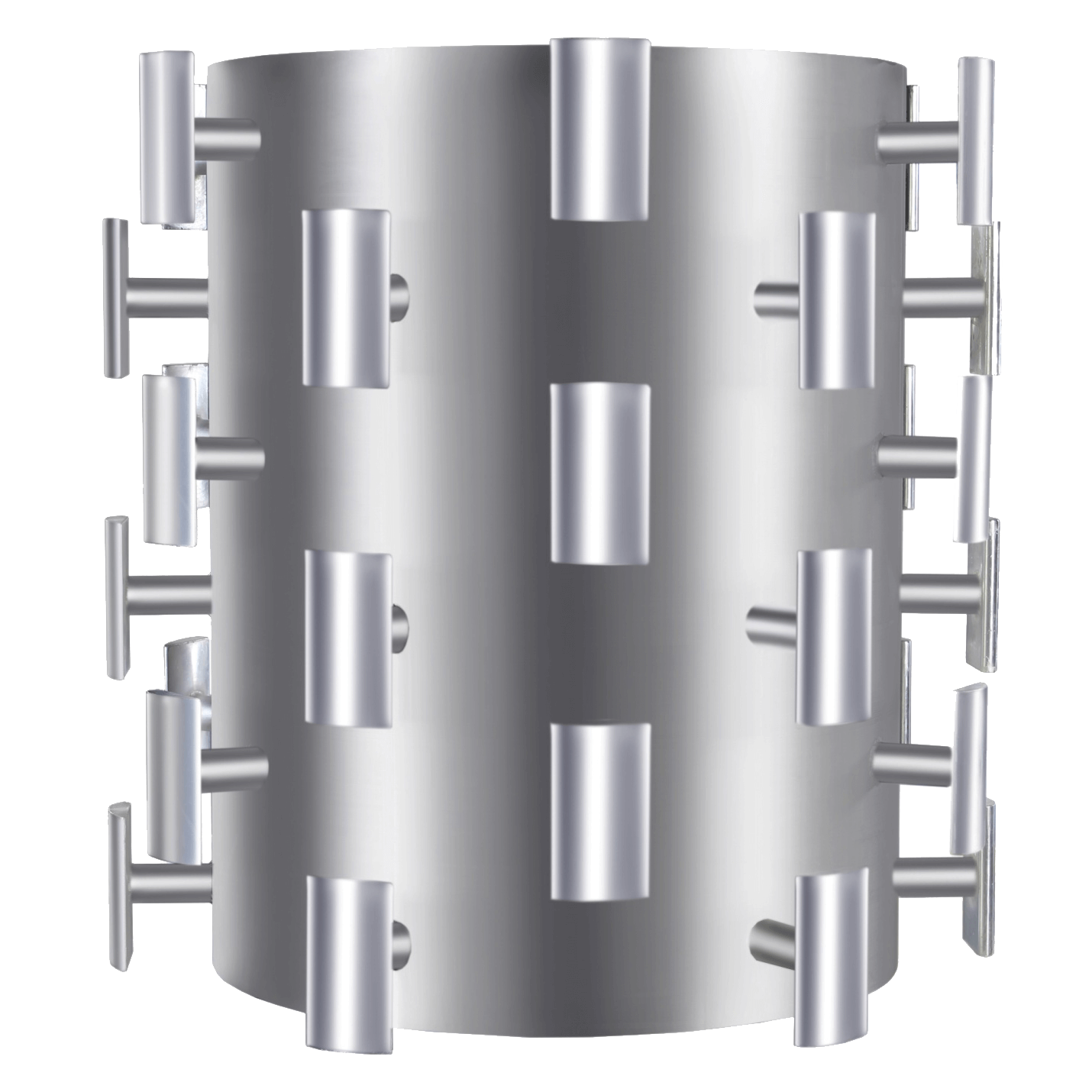

Rotor

Multilane Rotor for Perforated or Slotted Pressure Screens:

- Gentle screening

- Low consistency hole or slot basket

- Dynamically balanced rotor

- Multi vane aerofoil rotor

- Pulsation free rotor design

Special rotor design prevents string formation

Nath Screen

SLOTTED SCREEN BASKETS

The choice of appropriate screen baskets is extremely important in the pulp and paper industry. They can improve paper quality, elevate productivity and lower production costs, screen baskets manufactured by Nath SCREEN provide guaranteed quality and productivity.

Wedge wire bar type construction when designed and manufactured with superior technology effectively eliminates foreign substances and gives more open area and higher throughput and results in a stronger screen

In addition with our high technology in house Chroming surface treatment, we have increased screen life

Screen basket by Nath Screen guarantee lower production costs, raise productivity and improve the quality of your products.

- We supply screen baskets in various sizes from 300x300 to 1200x1200 as per drawings and dimensions details

Nath Screen

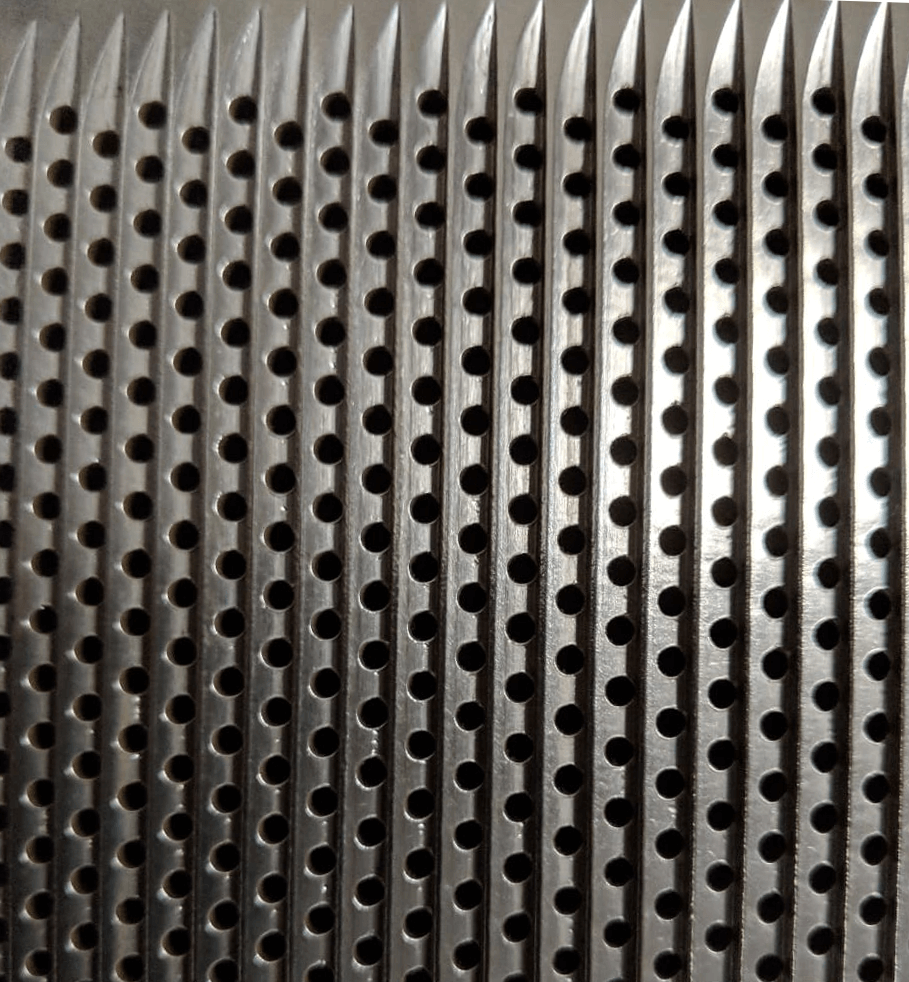

PROFILE HOLE SCREEN BASKET

The Nath Screen Profile hole screen basket offers precise and reliable technology for centrifugal pressure screens. They are ideal for use in stock preparation, as well as broke, pulp and approach flow screening.

The optimization of the pitch design leads to an achievement of the highest open screen areas and, as a result, to a high throughput. The high separation rates of dirt and impurities contribute to quality improvements in the end products. Constant advances in our manufacturing techniques yield the highest precision in different hole designs and roundness of the screen basket. Each screen basket is equipped with the Nath in house hard chrome-plating technology and possesses a high wear protection.